Intro

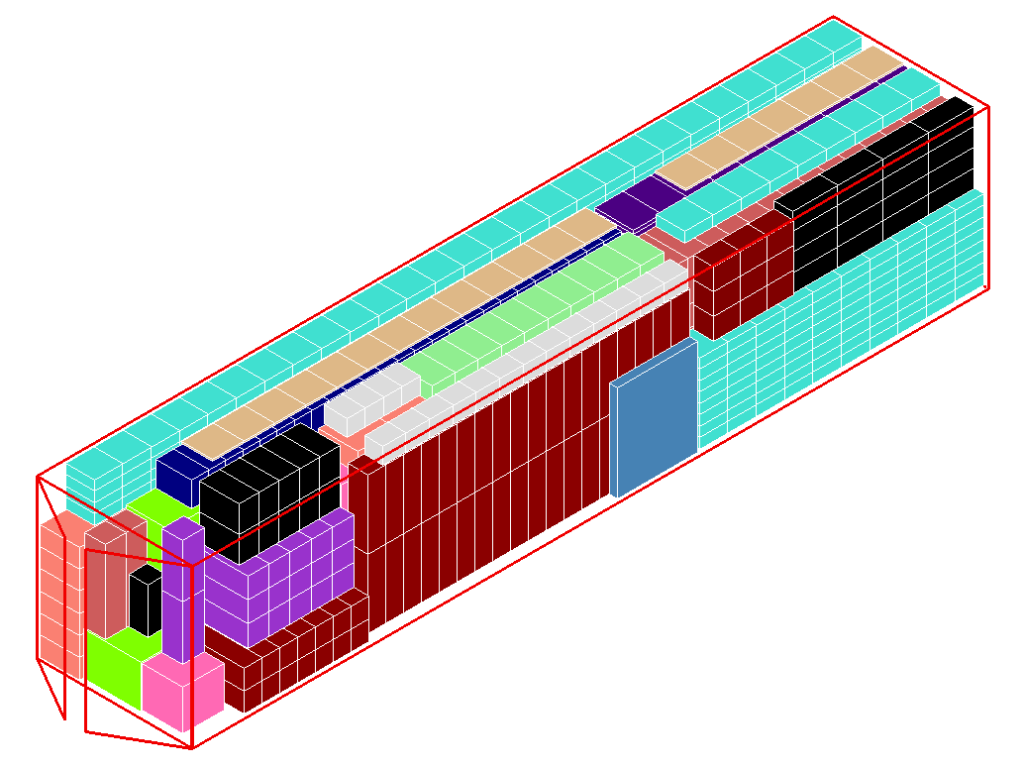

A client asked us to consolidate a full 40HQ container to Europe made up of many product categories. After sourcing and evaluating suppliers, we coordinated nine factories. What followed was a tightly scheduled, detail-driven operation — from sample testing and packaging alignment to on-site inspections and final customs coordination. Below is how we ran the project, the practical issues we solved, and why working with a supply-chain partner matters when complexity is high.

If you’re interested in the thinking behind our sourcing and risk-control approach, you may also like: From Transactions to Certainty: What Buyers Truly Pay for Is Peace of Mind.

This is how JXNUO turns complexity into certainty.